News about MABI Robotic

Well informed from the first source: Would you like first-hand information about the company and its products? MABI Robotic is looking forward to hearing from you!

Well informed from the first source: Would you like first-hand information about the company and its products? MABI Robotic is looking forward to hearing from you!

Electromobility undoubtedly has a promising future. With the growing demand for environmentally friendly means of transport and increased awareness of climate change, electric vehicles are becoming more and more important. An important factor for the future of electric mobility is to reduce production costs in order to make electric vehicles affordable for a broader population.

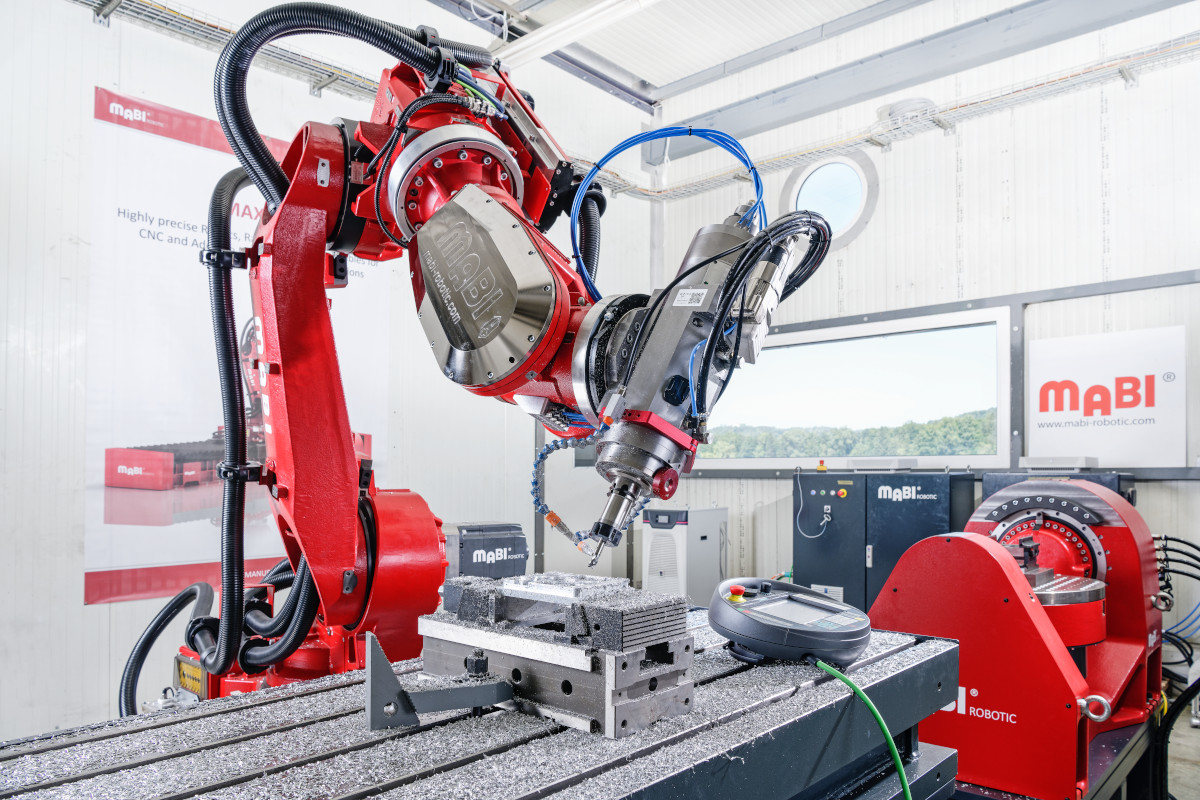

The MAX series CNC robots are therefore ideally suited to the production of battery trays.

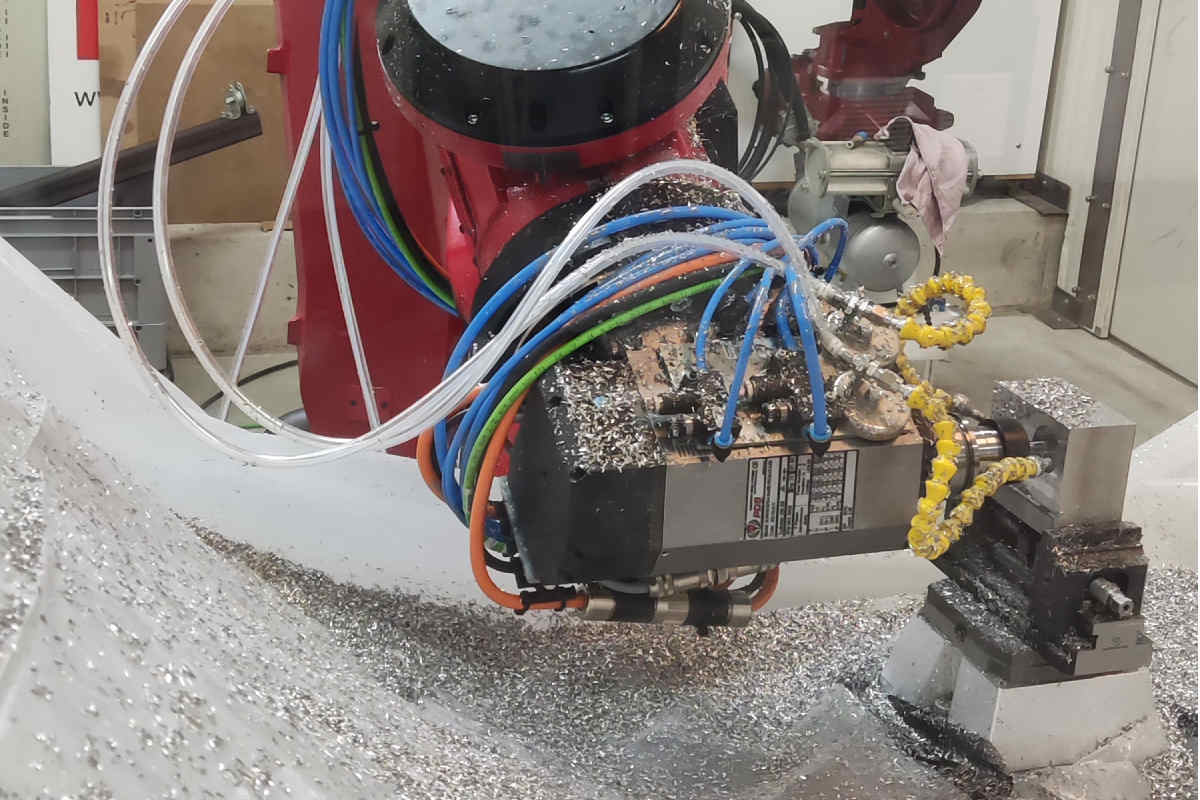

Several processes have already been tested and used in series production to manufacture the trays. Welded or die-cast aluminium trays are not yet finished after the basic body has been manufactured. In both cases, pockets, surfaces, holes, and threads have to be machined in one or more steps. Due to the size of the battery trays, a suitable machining centre is required, which is often associated with a large investment. The CNC milling robots from MABI Robotic are a more affordable alternative, as the energy efficiency is better and significantly fewer changes need to be made to the infrastructure due to the reduced footprint and lower overall weight. Thanks to the high stiffness and precise operation of the MAX series, we achieve similar accuracies to comparable portal milling machines.

We are pleased to announce CRENO as one of our first new partners. CRENO is located in France and known worldwide for its customised machining solutions in various industries. CRENO's numerous and well-known references are proof of the company's many years of experience and innovative power. The combination and strengths of CRENO and MABI offer cost-effective alternatives to expensive machine tools. The precise CNC milling robots from MABI Robotic are impressive due to their energy efficiency and minimal changes to the customer's existing infrastructure, as well as their flexibility thanks to the traversing axis and high accuracy. We are delighted to be able to offer our customers the powerful combination of the MABI robot controlled by Siemens CNC and integrated by CRENO, ensuring a tailored solution that precisely meets their needs. Contact us - and benefit from our expertise.

Milling and laser metal deposition (LMD) with our CNC robot at Toolcraft.

Franconian company Toolcraft AG has developed a robot cell that transforms a design file into a finished component - fully automatically.

VDI nachrichten Issue No. 3 from 09 February 2024 - Page 17

High-precision surface machining with the help of a robot at the Frauenhofer Institute IWU.

Zerspanungstechnik.de Blog 21. January 2024

To the article

Blog post from Unilube: The future of large part manufacturing

A milling machine with a workspace of 6x2m for under 200'000 CHF. Swiss-Made CNC industrial robot with open chip concept.

Unilube Blog Technik Talk 25. April 2022

Zum Beitrag

A robot with precision to rival a machine tool: This low-cost alternative to a CNC machine is suitable for numerous applications such as milling or surfacing. It was developed by the Aargauer company MABI Robotic AG, which relies on control, drives, spindle, control cabinet and software from Siemens.

Have you ever seen a robot milling? At the MABI Robotic booth, you could do just that. As the only exhibitor at the fair, a live milling show was demonstrated several times a day. Spectators could watch the spectacle up close. Watch the result in the video.

A mobile CNC robot application with a MABI MAX 100 was presented at the SIEMENS AG booth at Prodex 2019. The MAXRAIL traversing axis was specially developed for high-precision application scenarios so that friction forces can be compensated thanks to a master-slave drive as well as linear and high-resolution length measuring systems on the output side. In this way, it is possible to create optimum conditions for growing robot applications in the CNC sector.

Successful appearance of MABI Robotic AG at the world's largest industrial fair in Hannover. A mobile CNC robot application with a MABI MAX 100 was presented at the SIEMENS AG booth in Hall 9 of the Hannover Messe. The joint project of MABI with the Fraunhofer IFAM Institute and SIEMENS AG impressively shows how the high-precision robot kinematics of MABI Robotic AG together with the CNC control SINUMERIK 840 D from SIEMENS will change the milling of large structures in the future.

EN: Börse für Zukunftstechnologien – Leichtbautag in Stade bringt Unternehmen branchenübergreifend zusammen

Presseinformation vom 16. November 2017

EN: Roboter gelten als zu ungenau für Bearbeitungsaufgaben. Messtechnik kann das immer öfter ausgleichen.

Produktion Ausgabe Nr. 20 vom 20. September 2017

EN: Diese Roboter können ohne Schutzzaun mit Menschen zusammenarbeiten.

Produktion Ausgabe Nr. 13 vom 29. März 2017

EN: Leichtbaustruktur und hervorragendes Dämpfungsverhalten zeichnen Mabi Roboter aus.

Produktion Ausgabe Nr. 12 vom 22. März 2017

EN: Roboter on demand ermöglichen mobiles Bearbeiten von Flugzeugteilen mit hoher Präzision und Prozesssicherheit.

Produktion Ausgabe Nr. 10 vom 8. März 2017

EN: messekompakt.de News zur AUTOMATICA 2014 vom Mai 2014