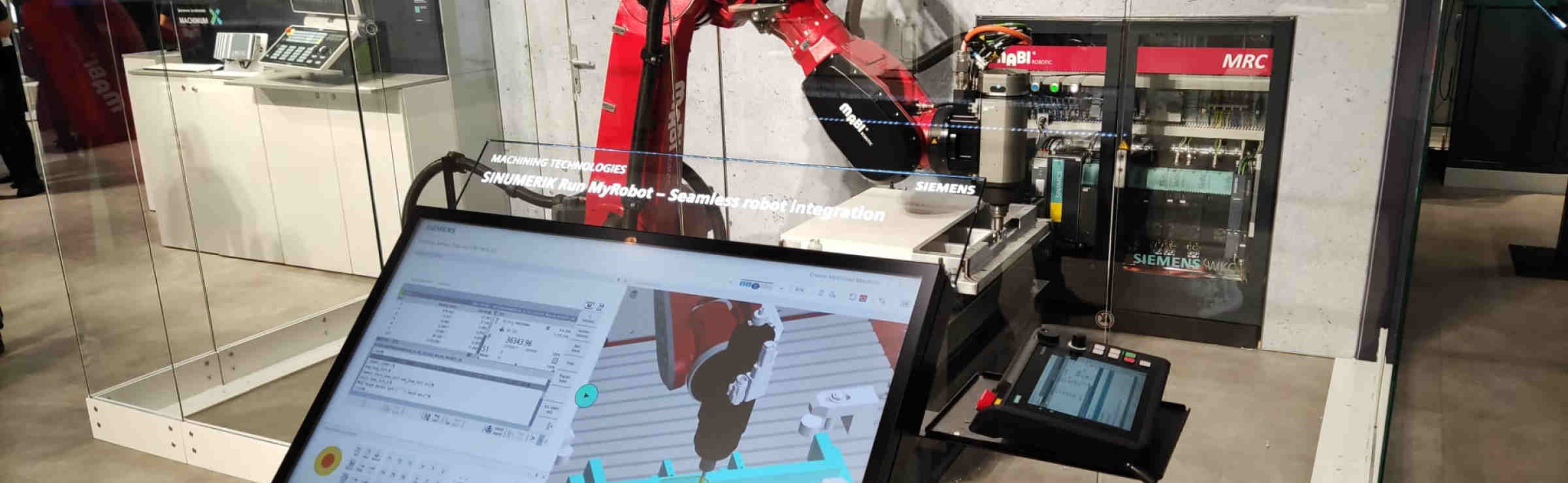

Processing of battery tray with industrial robot

Electromobility undoubtedly has a promising future. With the growing demand for environmentally friendly means of transport and increased awareness of climate change, electric vehicles are becoming more and more important. An important factor for the future of electric mobility is to reduce production costs in order to make electric vehicles affordable for a broader population.

The MAX series CNC robots are therefore ideally suited to the production of battery trays.

Several processes have already been tested and used in series production to manufacture the trays. Welded or die-cast aluminium trays are not yet finished after the basic body has been manufactured. In both cases, pockets, surfaces, holes, and threads have to be machined in one or more steps.

Due to the size of the battery trays, a suitable machining centre is required, which is often associated with a large investment. The CNC milling robots from MABI Robotic are a more affordable alternative, as the energy efficiency is better and significantly fewer changes need to be made to the infrastructure due to the reduced footprint and lower overall weight. Thanks to the high stiffness and precise operation of the MAX series, we achieve similar accuracies to comparable portal milling machines.

For further information or references, please contact us via the contact form or give us a call.