Applications of industrial robots for additive manufacturing

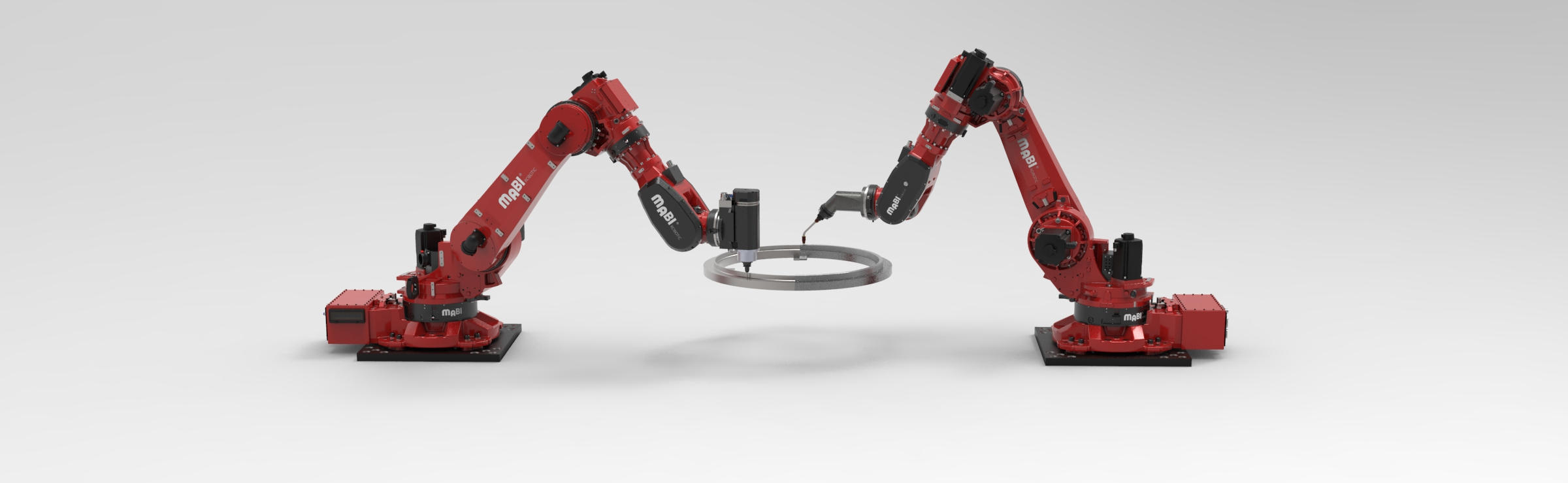

Additive manufacturing, also known as 3D printing, is a process by which three-dimensional objects are built up layer by layer. With conventional manufacturing methods, material is removed or moulded. By adding material, shapes can be produced that are not possible with other methods. The CNC robots from MABI Robotic AG are the optimum tool for large objects.

One of the best-known additive manufacturing processes is 3D printing. A layered model is created from a digital model using a slicer. Material, such as plastic or metal, is then applied layer by layer and joined together. The connection is created by melting the added material. In the case of plastic, a filament is often melted with a heating element or, in the case of a resin printer, the liquid is cured with a UV laser. The additive processes are similar for metal components and the most common method is a metal 3D printer, in which the component is built up with a laser and the metal powder added layer by layer. The use of laser deposition welding heads is used for larger objects. The metal powder is shot directly onto the component and melted with the laser. In this way, individual areas can be processed on an existing plate.

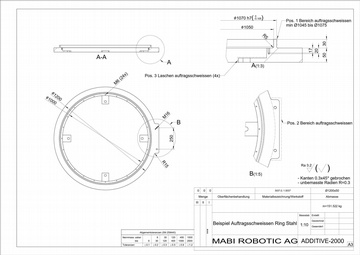

Additive manufacturing with CNC robots has enormous potential in large-scale production or for complicated components. As the object is built up layer by layer, individual adjustments can be made easily and cost-effectively. As a simple example, we could use a steel ring as shown in the illustrations. The raw material for the ring should have an outer diameter of approximately 1205 mm and a thickness of 90 mm. The amount of material to be processed is therefore enormous, one solution is to use our CNC robot. As noted in the drawing, we can produce items 1, 2 and 3 (raw material ring) by means of build-up welding and thus achieve high savings in raw material costs. The raw material still has an outside diameter of 1205 mm, but the height of the material has been reduced from 90 mm to 60 mm. That would be a 33% reduction in material costs. In combination with an exchangeable milling spindle, the workpiece can be machined directly after application.

This brief insight into the applications of CNC robots in additive manufacturing only covers a small part of the many possibilities. If you have any questions about the use of our CNC robots, we will be happy to provide you with information and support you in your project idea with our extensive knowledge. Contact us.